FULL CYCLE PRODUCTION

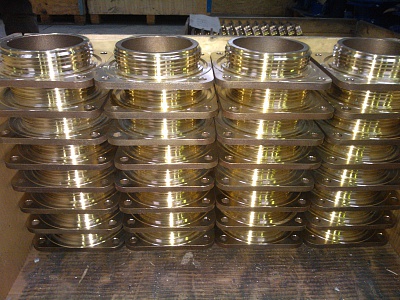

ENEKOS Group Ltd has its own mechanical production in Saint Petersburg, that is equipped with high-performance process equipment from the world’s leading brands of machine tool building, skilled production and managerial personnel.

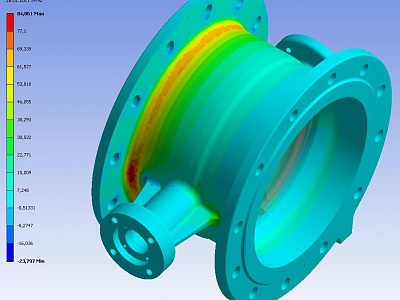

The production facilities cover all stages of fittings manufacture – from product development to testing and are able to assure serial release of valves and fittings complying with European quality standards.

During the entire production cycle we undertake thorough comprehensive control of quality of the released products, which allows maximum duration of the operation and warranty periods to be attained:

Flange butterfly valve:

Average service life - 50 years,

The manufacturer’s warranty - 5000 cycles or up to 10 years.

Wedge gate valve:

Average service life - 50 years,

The manufacturer’s warranty - 5000 cycles or up to 10 years .

Underground hydrant:

Average service life - 50 years,

The manufacturer’s warranty - 200 cycles, or up to 10 years.

Pipeline connector:

Average service life - 50 years,

The manufacturer’s warranty - 10 years.

Warranty service life - 10 years, average service life – 50 years.